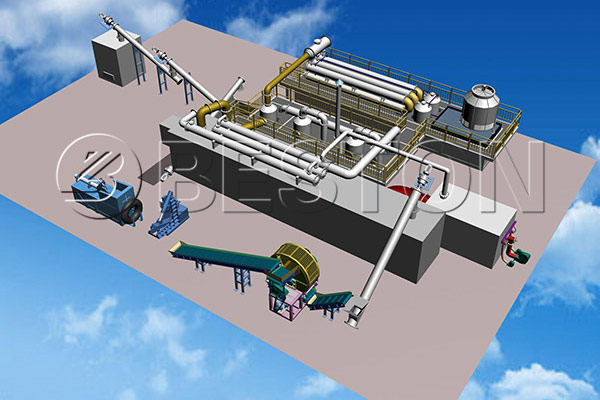

Finding the best tyre recycling machinery for sale should be your first step towards producing quality hydrocarbon gas, pyrolysis fuel and steel wire among other products. It is important to note that each brand of pyrolysis equipment has unique features. Nevertheless, there are common things that you should look for when buying your tyre recycling machinery. They include the following:

Technology

The technology used by the tyre recycling machinery that you choose is very important. The best machinery uses advanced technology that enables it to produce useful resources. Modern waste tyre recycling pyrolysis plant china enables the best machinery to convert waste tyres into carbon black, steel wire and tyre oil. These are useful resources that can be used in other applications. For instance, tyre oil can be used for burning purposes as industrial fuel or even refined further into gasoline or diesel. Carbon black on the other hand can be used to construct bricks or used as industrial fuel. Steel wire can be reprocessed or re-sold.

Output rate

Find out how fast the pyrolysis equipment works before you purchase it. If you want a tyre recycling machinery for use in a large pyrolysis company, look for tyre recycling machinery for sale that heats waste tyres quickly. This will enable your company to meet customers’ demand with ease. For instance, a company that supplies products globally should have a highly efficient machine to ensure their timely production. However, a smaller pyrolysis company can use slower machinery since the demand for its products is not very high.

Energy efficiency

Waste pyrolysis equipment may need more than 400 degree Celsius to recycle tyres. To achieve this temperature, the machinery consumes a lot of energy. However, not all tyre recycling machinery require this energy. Although some machines leave pyrolysis companies with enormous monthly energy bills, some consume a relatively low amount of energy. Therefore, consider the amount of energy that the tyre recycling machinery for sale requires to run efficiently before you purchase it. Ideally, make your choice depending on the amount of tyres that your plant intends to recycle every day.

Safety

How safe is the machinery to your employees? The most ideal pyrolysis equipment comes with a safety device. This can be an alarm that signals excess pressure and temperature, extra gas in the recycling system, auto pressure release system and fire fighting devices. These enable users to avoid injuries during the production process thereby guaranteeing their safety.

The most ideal tyre recycling machinery for sale is made in a way that ensures that only a little amount of combustible gas is produced during the recycling process. This gas can also be recycled and used as fuel that heats the reactor. This saves energy while reducing pollution. Additionally, the machinery comes with a ducting system that ensures effective de-dusting of the hot smoke that comes from the reactor. Over 95 percent of dust is usually removed by this system ensuring that the machinery releases a pollution-free gas that can be discharged to the air directly.

Generally, many companies give prices of the available tyre recycling machinery for sale priority. Although price is an important factor to consider, it is important to note that waste tyre recycling plant cost depends on these and other factors. Therefore, choose pyrolysis equipment that yields more value instead of focusing on price alone.