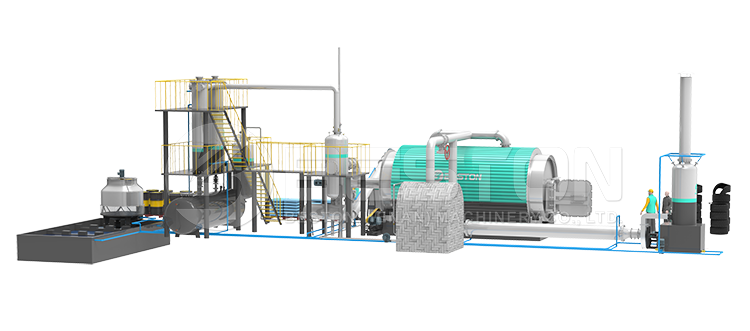

Sewage sludge carbonization plant is a recently created machine that proselytes sludge into bio-coal, a sort of strong biomass that can mostly substitute for coal amid power era. Carbonization is the best approach for sewage sludge treatment and disposal. To meet the solid market requests, our organization plans the new charcoal making machine.

The sludge treatment system boasts double-layer, which will make the lower part of the machine contact the hot air however much as could be expected, in the interim, this outline will be useful to raise the warmth usage proficiency from the earliest starting point. The upper piece of sewage sludge unit receives edge driving and focus screening twofold drive and step-less speed change structure, which can mandatorily change the materials into fine powder in a blaze steaming and drying chamber and the powder can completely contact the hot air and we can get material with similar mugginess in spite of the fact that their underlying moistness is distinctive. Besides, “one fire two-stage strategy carbonizing framework” is the unparalleled on the planet. At present, there is no other development apparatus could be said with us at similar minute. More details can be found on the coconut shell charcoal making machine.

Working principle of carbonizing machine

Vanishing stage: predominantly relying upon the warmth created by blazing crude material itself and fuel, the dampness begins steaming from start to the temperature of heater ascending to 160 . There is no change of synthetic organization.

Introductory stage: this stage predominantly relies on upon the warmth created by blazing crude material, which rises the temperature of the carbonizing furnace to somewhere around 160 and 280. As of now, the crude material starts to turn out warm disintegration.

Add up to carbonization stage: the most reasonable temperature is somewhere around 280 and 400. Amid this stage, crude material begins strongly warm decay and dangerous refining to charcoal with high temperature. Get high-quality biochar production equipment here.

1. Use as the fuel with the charcoal.

2. Sell in the market as the fuel with the coal.

3. Fill some construction material to give road water permeable brick.

4. Use as the active carbon for raffle water was recycling.

5. Use as the carbon-based organic fertilizers for the garden and plant.

6. Use as the active carbon for other usages.

7. The garbage water can be sold to thermal power plant for wetting fly ash or secondary processing.

Principle Advantages of Sludge Charcoal Production Plant:

1. Simple operation, work sparing and no hazard.

2. Natural well disposed with one of a kind smoke cleaning gear.

3. High yield rate and efficient.

4. Durable with exceptional materials.

5. Top review item quality.

It explains why people would like to invest a sawdust charcoal making machine.