The Diverse Roles Of Electric Rebar Bending Machines

Over the past few decades, reinforced concrete has gone from being one of many potential structural materials to being virtually a default option. This has led to greatly increased demand for the specialized tools required to work with reinforced concrete efficiently. These include electric rebar benders, purpose-built machines designed to bend heavy iron reinforcing bars quickly and efficiently.

Portable Vs. Production Benders

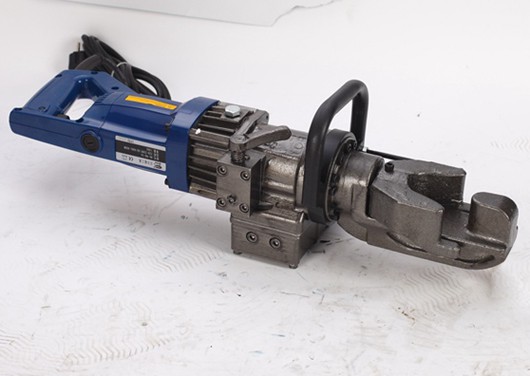

While there are dozens (possibly hundreds) of different rebar benders for sale today, they can be broadly categorized according to their overall size and portability. The lightest benders are man-portable and can be used virtually anywhere. These machines typically rely on manual operator input to dictate the way in which they bend rebar.

Shop or site benders are much larger, weighing hundreds or thousands of pounds. These machines are employed both on job sites and in shops and factories. They offer a much greater precision and speed than their hand-held counterparts, but they also require more infrastructure (e.g. power and hydraulics) and a higher degree of training. These benders can typically be relocated from day to day, and they’re used on site to perform large numbers of bends at a central location.

The largest rebar bending machines are production benders. These are intended to be installed permanently in a facility devoted to the full-time production of finished rebar. They have the highest capacity and greatest flexibility of all the bending machines, but they are (obviously) non-portable.

Function Following Form

With a little thought, you can easily extrapolate each type of bender’s intended function based on its size and shape. Hand-held benders are intended for ad-hoc bends that are carried out on rebar that’s in place. They’re ideal for correcting minor errors and performing last-minute modifications.

Site benders are perfect for handling repetitive bends that are required in large numbers on a larger project. Creating Ls or stirrups for a major foundation slab would be an example.

Production benders are designed for two roles: the efficient creation of large volumes of stock rebar and the precise creation of highly customized orders. Production benders offer the widest range of settings and adjustments that can be made to alter their output in subtle or significant ways.

Typical Rebar Bending Operations

With smaller rebar benders, the vast majority of bends performed are simply adding a single angle to a piece of straight rebar. Creating curved forms is frequently handled with specialized attachments or jigs that produce hooks, loops, circles, and arcs in commonly-needed dimensions.

More complex shapes of bent rebar typically require larger benders, machines designed for site or production use. The biggest and most capable machines can turn out shapes of practically infinite variety, from zigzags used to reinforce staircases to precisely-curved bars intended for use in walls with complex geometry.

Modern electric rebar benders http://rebarprocessingequipment.com/electric-rebar-bender/ come in a huge array of different forms, and they’re used in many different parts of the construction industry. With few exceptions, they perform with admirable efficiency and reliability, greatly speeding up the pace and precision of construction work.